A hand saw with a guide is a versatile tool designed for precise cutting in woodworking, carpentry, and gardening. It combines a high-quality blade with a guiding mechanism to ensure accuracy and control, making it ideal for both professionals and hobbyists. The use of a guide enhances stability, reducing the risk of uneven cuts and improving overall performance. Proper grip, stance, and technique are essential for maximizing the tool’s potential, as highlighted in various woodworking guides and tutorials.

Whether you’re cutting intricate joints or trimming branches, a hand saw with a guide offers unmatched precision and efficiency. Its ergonomic design and durable construction make it a reliable choice for a wide range of applications, from fine woodworking to heavy-duty tasks. By mastering the techniques and maintaining the tool, users can achieve professional-grade results with minimal effort.

1.1 Definition and Purpose

A hand saw with a guide is a tool designed for precise cutting, combining a high-quality blade with a guiding mechanism to enhance accuracy. Its primary purpose is to make clean, controlled cuts in various materials like wood, metal, or plastic. The guide ensures stability, reducing wobble and improving the quality of the cut. This tool is essential for woodworking, carpentry, and gardening, offering versatility and reliability for both professionals and hobbyists. Its design allows for efficient use, making it a cornerstone in many workshops and toolkits.

The saw’s guide helps maintain a straight cutting path, minimizing errors and ensuring consistent results. Whether for intricate joints or general cutting tasks, it provides the precision needed for professional-grade outcomes. Its ergonomic design and durable construction make it a long-lasting investment for anyone requiring accurate cuts. By combining traditional craftsmanship with modern innovations, the hand saw with a guide remains a indispensable tool for various projects.

1.2 Historical Background

Hand saws with guides have evolved from ancient tools used in woodworking and carpentry. Early civilizations developed saws with rudimentary guides to improve cutting accuracy. The modern version incorporates advanced materials and designs, enhancing precision and control. Historically, these saws were essential in shipbuilding, furniture making, and construction. Their design has remained largely consistent, with the guide mechanism being a key innovation that distinguishes them from standard hand saws. Over time, the tool has adapted to new materials and techniques, maintaining its relevance in both traditional and contemporary applications;

The historical development of hand saws with guides reflects the need for precision in craftsmanship. From wooden handles to steel blades, the tool has undergone significant improvements. Today, it remains a vital instrument for professionals and hobbyists alike, blending historical craftsmanship with modern functionality. Its enduring popularity underscores its effectiveness in achieving accurate and efficient cuts across various materials.

1.3 Benefits of Using a Hand Saw with Guide

Using a hand saw with a guide offers numerous advantages, primarily enhanced precision and control. The guide ensures straight, accurate cuts, reducing waste and improving efficiency. It is particularly useful for intricate woodworking projects, such as dovetail joints, where exactness is crucial. Additionally, the tool minimizes the risk of binding, allowing smoother cuts with less effort. Its portability and lack of electricity dependency make it ideal for various settings, from workshops to outdoor tasks. Moreover, the guide mechanism simplifies the sawing process for beginners, making it accessible to a broader range of users.

The ergonomic design of most hand saws with guides promotes comfort during extended use, reducing fatigue. This feature is especially beneficial for professionals who rely on precision and endurance in their work. Overall, the combination of accuracy, ease of use, and versatility makes a hand saw with a guide an indispensable tool for both professionals and hobbyists, ensuring high-quality results across different projects and materials.

Types of Hand Saws with Guides

Hand saws with guides come in various types, each designed for specific tasks. Rip saws, crosscut saws, and back saws are common, offering precision for woodworking projects, while pruning saws excel in gardening. Dovetail saws are ideal for fine joints, ensuring accuracy and cleanliness in intricate cuts. Each type caters to different needs, providing versatility and efficiency for both professionals and DIY enthusiasts.

2.1 Rip Saws

Rip saws are specialized tools designed for cutting wood along the grain, making them ideal for tasks like ripping lumber into thinner boards. Equipped with a guide, they ensure straight, consistent cuts. The saw’s teeth are typically coarse, allowing for efficient removal of material. Proper technique involves maintaining a steady grip and using the guide to align the blade. This results in smooth, accurate cuts. Rip saws are essential for woodworking projects requiring precise dimensional lumber. They are durable and versatile, suitable for both professionals and hobbyists. Regular maintenance ensures optimal performance.

2.2 Crosscut Saws

Crosscut saws are designed for cutting wood across the grain, making them ideal for tasks like trimming boards to size. They typically feature finer teeth than rip saws, resulting in smoother cuts. The guide ensures accuracy, keeping the blade aligned for straight cuts. These saws are perfect for woodworking projects requiring precise joints and clean finishes. Proper technique is essential for optimal performance, making crosscut saws a valuable tool for both professionals and hobbyists. Regular maintenance ensures longevity and consistent results.

2.3 Back Saws

Back saws are specialized tools with a rigid metal or polymer spine reinforcing the blade, ensuring straight, precise cuts. They are commonly used in woodworking for tasks like cutting joints and fine detailing. The guide enhances stability, making them ideal for intricate work. With fewer teeth, back saws produce smooth finishes and are often used in cabinetry and furniture making. Proper grip and alignment are crucial for achieving accurate results, making them a must-have for woodworkers seeking precision and control in their projects.

2.4 Dovetail Saws

Dovetail saws are designed specifically for cutting precise joints, such as dovetails, in woodworking projects. They feature a narrow blade with fine teeth, allowing for tight, accurate cuts in small spaces. Often used in cabinetry and furniture making, these saws are essential for creating strong, interlocking joints. The guide ensures straight cuts, while the rigid spine maintains stability. Proper technique, including a firm grip and consistent stroke, is key to achieving clean, professional results. They are a must-have tool for woodworkers focused on intricate joinery and fine detailing.

2.5 Pruning Saws

Pruning saws are specialized tools for gardening and landscaping, designed to cut branches and shrubs with precision. They typically feature curved or angled blades, allowing for easy access to hard-to-reach areas. The guide ensures straight, clean cuts, minimizing damage to surrounding plants. These saws often have rust-resistant coatings and ergonomic handles for comfort during extended use. Ideal for both professionals and homeowners, pruning saws are essential for maintaining healthy plants and achieving neat, manicured landscapes with minimal effort and maximum efficiency.

Materials and Construction

Hand saws with guides are crafted from high-quality materials, including carbon steel blades for durability and sharpness, paired with ergonomic handles for comfort and reduced fatigue.

3.1 Blade Materials

Hand saw blades are typically made from high-carbon steel, known for its durability and ability to hold a sharp edge. This material ensures longevity and consistent performance, making it ideal for precise cuts. Some blades feature chrome plating to enhance rust resistance and reduce friction, ensuring smoother cuts and extended blade life. High-quality saws may also use specialized alloys for specific tasks, such as cutting hardwoods or metals, providing superior strength and wear resistance. Properly maintained, these blades retain their sharpness and deliver accurate results.

3.2 Handle Designs

Hand saw handles are crafted from durable materials like wood, composite plastics, or metal, ensuring a comfortable and secure grip. Ergonomic designs prioritize user comfort, with contoured shapes that reduce fatigue during extended use. Some handles feature rubber or cork coatings for enhanced traction, minimizing slippage even with sweaty hands. The design often includes a balanced weight distribution, allowing for precise control and smooth cutting motions. A well-designed handle maximizes efficiency and reduces strain, making it easier to achieve accurate cuts consistently.

3.3 Ergonomic Features

Modern hand saws with guides incorporate ergonomic features to enhance user comfort and reduce fatigue. Contoured handles with cushioned grips provide a secure hold, while balanced designs distribute weight evenly for effortless cutting. Some models feature adjustable handles to fit various hand sizes, ensuring a personalized fit. Anti-vibration technology minimizes strain during use, and angled grips promote natural wrist alignment, reducing the risk of injury. These ergonomic advancements ensure that users can work efficiently and safely, even during prolonged projects.

Choosing the Right Hand Saw for Your Needs

Selecting the ideal hand saw involves considering its purpose, tooth count, and handle design. Match the saw type to your project needs for optimal results and comfort.

4.1 Purpose and Application

The purpose of a hand saw with a guide is to achieve precise, controlled cuts in various materials. Its application depends on the type of project, such as woodworking, carpentry, or gardening. For woodworking, rip saws are ideal for cutting with the grain, while crosscut saws are better for cutting across the grain. Back saws are perfect for fine joinery, and dovetail saws excel at creating precise joints. Pruning saws, on the other hand, are designed for trimming branches and shrubs. Choosing the right saw ensures efficiency and accuracy for the task at hand.

4.2 Tooth Count and Size

The tooth count and size of a hand saw with a guide are critical for achieving the desired cut quality. Tooth count, measured in teeth per inch (TPI), determines how smooth or aggressive the cut will be. Higher TPI (14-20) results in finer cuts, ideal for woodworking and precision tasks, while lower TPI (8-12) is better for faster, rougher cuts in thicker materials. Tooth size also matters, with larger teeth removing material quickly and smaller teeth offering more control and accuracy.

Choosing the right tooth count and size depends on the material and desired outcome. For fine woodworking, higher TPI is preferred, while for general-purpose tasks, a lower TPI is more efficient. Always match the tooth configuration to your project needs for optimal performance and results.

4.3 Handle and Grip Preferences

The handle and grip of a hand saw with a guide play a crucial role in comfort and control. Traditional handles are often made from wood or metal, while modern designs incorporate ergonomic materials like rubber or composite plastics for better grip. A well-designed handle reduces fatigue and improves accuracy, especially during extended use. Ensure the handle fits comfortably in your hand, allowing for a firm yet relaxed grip.

Some users prefer a pistol grip for power and leverage, while others favor a straight or contoured grip for precision. The choice depends on personal comfort, the type of saw, and the specific task. A secure grip ensures better control, reducing the risk of slips and inaccurate cuts. Always consider handle material and design when selecting a hand saw for optimal performance and comfort.

Techniques for Using a Hand Saw with Guide

Mastering proper grip, stance, and sawing motion is essential for accurate cuts. Start with a gentle touch, gradually increasing pressure while maintaining guide alignment for precision and control.

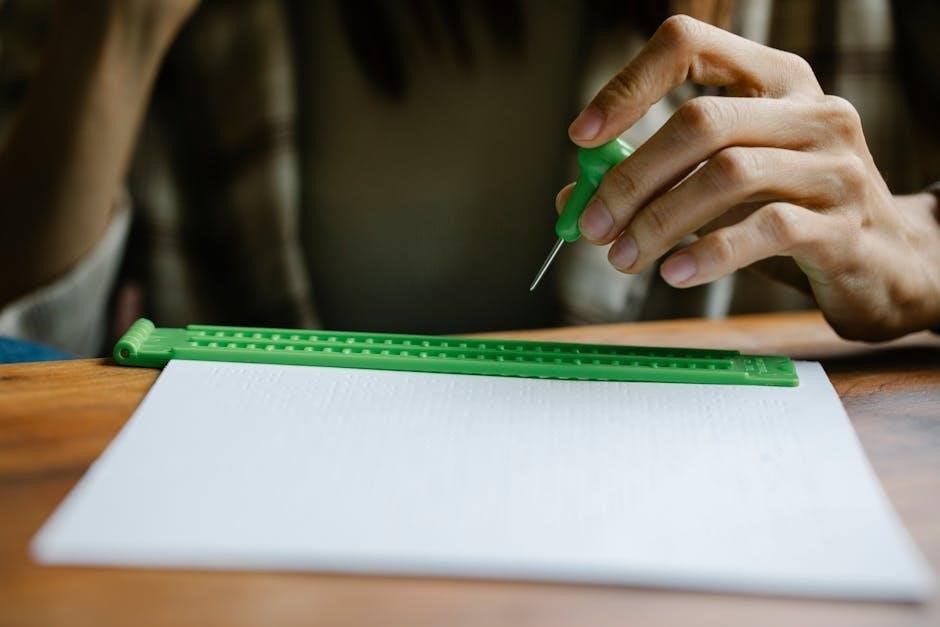

5.1 Proper Grip and Stance

A proper grip and stance are fundamental for effective use of a hand saw with a guide. Hold the handle firmly with your dominant hand, ensuring a comfortable yet secure grasp. Use your other hand to guide the blade, maintaining light pressure for stability. Stand with feet shoulder-width apart, knees slightly bent, and body balanced evenly. Keep your arms relaxed, using your shoulders and core to generate power. Proper posture prevents fatigue and ensures precise, controlled cuts. A consistent grip and stance are key to achieving accurate results.

5.2 Starting the Cut

Starting the cut with a hand saw requires precision and patience. Begin by marking the cut line clearly on the material. Place the saw teeth on the waste side of the line at a 45-degree angle to the surface. Gently pull the saw upward to create a small notch, ensuring the blade is aligned with the guide. This notch provides a stable starting point. Use a light, controlled motion to begin the cut, keeping the saw steady and allowing the teeth to engage the material gradually. Avoid applying excessive pressure initially to maintain accuracy and prevent the blade from binding.

5.3 Maintaining Accuracy

Maintaining accuracy with a hand saw requires focus and consistent technique. Use the guide to keep the blade aligned with the marked cut line, ensuring straight and precise cuts. Apply steady, controlled pressure, avoiding uneven force that could cause the blade to wander. Keep the saw at a consistent angle and monitor the blade’s alignment with the guide throughout the cut. By leveraging the guide’s stability and maintaining proper form, you can achieve clean, accurate results with minimal effort.

5.4 Applying Pressure

Applying pressure with a hand saw requires balance and control. Use your upper body weight to power the saw, keeping your arm relaxed. Apply steady, even pressure to maintain consistent cutting speed. Avoid applying too much pressure, as this can cause the blade to bind or wander. Instead, let the saw’s teeth do the work, using gentle to moderate pressure depending on the material. Maintain the blade’s alignment with the guide to ensure straight cuts and prevent inaccuracies. Proper pressure application enhances efficiency and reduces fatigue.

Safety Precautions

Always wear protective gear, including gloves and eye protection, to prevent injuries from sawdust and debris. Ensure the workspace is clean and well-lit to maintain visibility and control.

6.1 Protective Gear

Protective gear is essential when using a hand saw with a guide to ensure safety and prevent injuries. Always wear safety glasses or goggles to shield your eyes from sawdust and debris. High-quality gloves with a firm grip are recommended to prevent slipping and protect your hands from splinters. Additionally, consider wearing long sleeves and a dust mask, especially when working with treated wood or in dusty environments. Proper protective equipment ensures a safer and more controlled cutting experience, reducing the risk of accidents and injuries.

6.2 Workspace Preparation

Proper workspace preparation is crucial for safe and effective use of a hand saw with a guide. Clear the area of clutter and ensure the workpiece is securely clamped or held stable to prevent movement during cutting. Use a sturdy workbench or sawhorse to support the material, and ensure good lighting to maintain visibility. Protect your work surface with a cutting mat or old sheets to prevent damage. Keeping the area organized and hazard-free minimizes distractions and reduces the risk of accidents, allowing you to focus on precise, controlled cuts.

6.3 Avoiding Common Mistakes

Avoiding common mistakes when using a hand saw with a guide ensures safety and effectiveness. One frequent error is applying too much pressure, which can cause the blade to bind or the material to split. Another mistake is not maintaining a steady, consistent stroke, leading to uneven cuts. Additionally, failing to keep the workpiece firmly secured can result in loss of control. Always start with a gentle touch, gradually increasing pressure as needed, and keep the saw aligned with the guide to maintain accuracy and prevent accidents.

Maintenance and Care

Regular cleaning prevents rust and maintains blade effectiveness. Store the saw in a dry place to avoid damage. Sharpen the blade periodically for optimal performance and inspect the handle for wear.

7.1 Cleaning the Saw

Cleaning the hand saw is essential for maintaining its performance and longevity. Use a soft cloth to wipe away sawdust and debris from the blade and handle after each use. For tougher residue, mix mild soap with warm water, and gently scrub the blade with a soft-bristle brush. Rinse thoroughly and dry with a clean cloth to prevent rust. Apply a light coat of oil to the blade to protect it from corrosion. Avoid using harsh chemicals, as they may damage the handle or blade. Regular cleaning ensures optimal functionality and precision in future cuts.

7.2 Storing the Saw

Proper storage is crucial for maintaining the longevity and performance of your hand saw with a guide. After cleaning, store the saw in a dry, cool place to prevent rust and corrosion. Use a protective case or hang it on a hook to avoid damage. Apply a light coat of oil or silicone spray to the blade for added protection. Avoid storing in humid environments or direct sunlight, as this can cause metal degradation or handle fading. Regularly inspect the saw for any signs of wear or rust, and ensure it is completely dry before storage to preserve its quality and functionality.

7.3 Sharpening the Blade

Sharpening the blade of your hand saw with a guide is essential for maintaining its performance and extending its lifespan. Begin by inspecting the blade for dull or damaged teeth. Use a whetstone or diamond file to sharpen the teeth, ensuring the angle matches the manufacturer’s specifications. Maintain consistency across the blade to avoid uneven cutting. After sharpening, test the blade on scrap wood to ensure it cuts smoothly. Regular sharpening prevents the blade from binding and improves accuracy, keeping your saw in optimal condition for precise cuts.

Advanced Tips for Mastering the Hand Saw

Mastering a hand saw with a guide requires consistent practice, precise technique, and attention to blade maintenance. Advanced users refine their skills by focusing on smooth, controlled strokes and leveraging the guide for exceptional accuracy. Regular sharpening and proper handling ensure optimal performance, enabling intricate cuts and professional-grade results in woodworking and other applications.

8.1 Practicing Sawing Techniques

Mastering sawing techniques requires consistent practice and patience. Start by practicing straight cuts on scrap wood to develop muscle memory and control. Focus on maintaining a steady grip and using the guide for precision. Gradually progress to angled and curved cuts to improve versatility. Pay attention to the saw’s tooth orientation and apply gentle, consistent pressure. Regular practice enhances accuracy and confidence, allowing you to tackle complex projects with ease. Dedication to refining these skills will elevate your craftsmanship and ensure professional-grade results.

8.2 Using Guides for Precision

Using a guide with your hand saw ensures precise cuts by aligning the blade accurately along the marked line. The guide helps maintain stability, reducing wobble and preventing deviations. For straight cuts, place the guide firmly against the material, keeping the saw blade flush with the edge. This setup allows for consistent control, especially when cutting intricate shapes or angled joints. By relying on the guide, you can achieve professional-grade accuracy with minimal effort, making it an indispensable tool for detailed woodworking and craftsmanship.

8.3 Cutting Different Materials

A hand saw with a guide excels at cutting various materials, from wood and plastic to metal and drywall. For wood, a sharp, high-tooth-count blade ensures smooth cuts, while metal requires a coarse, rigid blade. Plastic and drywall can be cut with finer teeth for clean edges. The guide ensures straight, precise cuts regardless of the material. By adjusting the blade type and technique, you can tackle diverse projects with confidence, making the hand saw with a guide a versatile tool for any workshop or job site.

Common Applications

Hand saws with guides are commonly used in woodworking, carpentry, and gardening. They excel in cutting joints, trimming branches, and handling various DIY projects efficiently and precisely.

9.1 Woodworking Projects

Hand saws with guides are indispensable in woodworking projects, offering precision for cutting joints, trimming wood, and creating intricate designs. They are ideal for cabinetry, furniture making, and crafting dovetail joints, ensuring clean, accurate cuts. The guide enhances control, making it easier to follow cut lines, especially in complex designs. Whether cutting thin panels or thick lumber, these saws deliver consistent results, making them a must-have tool for woodworkers aiming for professional-grade finishes. Their versatility and reliability make them suitable for both small-scale crafts and large woodworking endeavors.

9.2 Carpentry and Framing

Hand saws with guides are essential tools in carpentry and framing, offering precision for cutting large timbers and beams. They are particularly useful for making straight, accurate cuts in structural lumber, ensuring proper fit and alignment. The guide helps maintain a steady line, reducing errors in critical joints. Rip saws, with their aggressive teeth, are often used for cutting with the grain in framing tasks. For carpenters, these saws provide the control needed for precise notches and sills, making them indispensable in both residential and commercial construction projects where durability and accuracy are paramount.

9.3 Gardening and Landscaping

Hand saws with guides are invaluable in gardening and landscaping for pruning and shaping plants. Their precision allows for clean cuts on branches, promoting healthy growth and maintaining aesthetic appeal. The guide ensures straight, accurate cuts, even in tight spaces, making them ideal for trimming shrubs or cutting small trees. Portable and lightweight, these saws are easy to maneuver, reducing fatigue during extended use. They are particularly useful for detailed work, such as shaping topiaries or removing deadwood, making them a essential tool for gardeners seeking precise and efficient results.

Troubleshooting Common Issues

Common issues with hand saws include blade binding and inaccurate cuts. Proper technique, blade maintenance, and guide alignment can resolve these problems, ensuring smooth operation and precision.

10.1 Blade Binding

Blade binding occurs when the saw blade gets stuck during a cut, often due to misalignment or improper technique. To resolve this, ensure the blade is properly lubricated and aligned with the guide; Applying gentle, consistent pressure while maintaining the correct angle can help prevent binding. If the issue persists, check for debris or damage on the blade and guide. Regular maintenance and proper storage can also minimize the risk of blade binding, ensuring smooth and efficient cutting.

- Ensure proper blade lubrication.

- Align the blade with the guide accurately.

- Apply consistent, gentle pressure.

- Inspect for debris or damage regularly.

10.2 Inaccurate Cuts

Inaccurate cuts often result from improper grip, misaligned guides, or uneven pressure. To address this, ensure the saw blade is correctly positioned and aligned with the guide. Using consistent, light strokes and maintaining proper body posture can improve accuracy. Regularly inspect the blade for sharpness and the guide for damage. Proper maintenance and technique refinement are key to achieving precise cuts. Practice on scrap material to develop muscle memory and control, ensuring your cuts align with your intended marks.

- Check blade sharpness and guide alignment.

- Use consistent, light strokes.

- Inspect for damage or wear.

- Practice on scrap material.

10.3 Handle Wear and Tear

Handle wear and tear can affect the performance and comfort of using a hand saw with a guide. Regular inspection is crucial to identify signs of damage, such as cracks or splinters. To prevent wear, store the saw in a dry place and avoid exposing the handle to harsh chemicals. Wearing gloves can reduce friction and extend the handle’s lifespan. If damage occurs, consider replacing the handle or using a reinforcing wrap to maintain grip and control.

- Inspect handles regularly for cracks or splinters.

- Store in a dry, protected environment.

- Use gloves to reduce friction and wear.

Comparison with Power Saws

Hand saws with guides offer precision and control, ideal for detailed work, while power saws prioritize speed and efficiency for larger projects. Choose based on task complexity and time constraints.

- Hand saws excel in intricate cuts and small-scale tasks.

- Power saws are better for rapid, heavy-duty cutting.

11.1 Speed and Efficiency

Hand saws with guides are slower but offer unmatched precision, while power saws deliver rapid cuts, making them ideal for large-scale projects. For detailed work, hand saws shine with their ability to maintain accuracy, even if progress is slower. Power saws, however, save time and effort, especially in bulk cutting tasks. The choice depends on the project’s demands, balancing speed and the need for exactness. Each tool excels in its domain, catering to different priorities in woodworking and carpentry.

- Power saws dominate in speed for heavy-duty tasks.

- Hand saws with guides prioritize precision over pace.

11.2 Precision and Control

Hand saws with guides excel in precision, allowing for accurate cuts with manual control. The guide enhances stability, ensuring straight and clean cuts, especially in intricate woodworking. Power saws, while faster, often lack the finesse needed for detailed work. Hand saws enable precise alignment and control, making them ideal for small, complex projects requiring high accuracy. The ability to manually adjust the blade’s position ensures superior control, particularly in delicate or custom cuts where machine precision falls short.

- Manual control ensures precise cuts in detailed work.

- Guides improve alignment and reduce errors.

- Power saws lack the finesse for intricate tasks.

Cost and Accessibility

11.3 Cost and Accessibility

Hand saws with guides are generally more affordable and accessible compared to power saws. They require no electricity, making them cost-effective and portable. The initial investment is lower, and maintenance costs are minimal, as sharpening and cleaning are straightforward. This makes them ideal for hobbyists and professionals alike. Their accessibility ensures that anyone can start woodworking or carpentry without significant financial barriers. Additionally, their simplicity reduces dependency on power tools, making them a practical choice for various projects.

- Lower upfront and maintenance costs.

- No electricity required for operation.

- Portable and easy to store.